Typical functions requiring an EDX specialist are automated and therefore samples can be analyzed by a novice. The EDX-LE permits high-speed screening of five RoHS-controlled elements plus chlorine (as an option). EDX-LE takes just 1 minute from the start of measurement to results evaluation (depending on the sample).

In addition to the high-speed screening, it maintains a high level of analysis reliability.

Start measurements just 15 minutes after turning on the power.

Measurement stops immediately after the target elements have been evaluated to save time, while ensuring highly sensitive and reliable analysis. Simple single-point calibration curves are registered in the instrument to allow quantification without the need for standard samples.

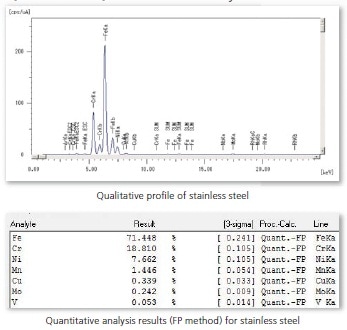

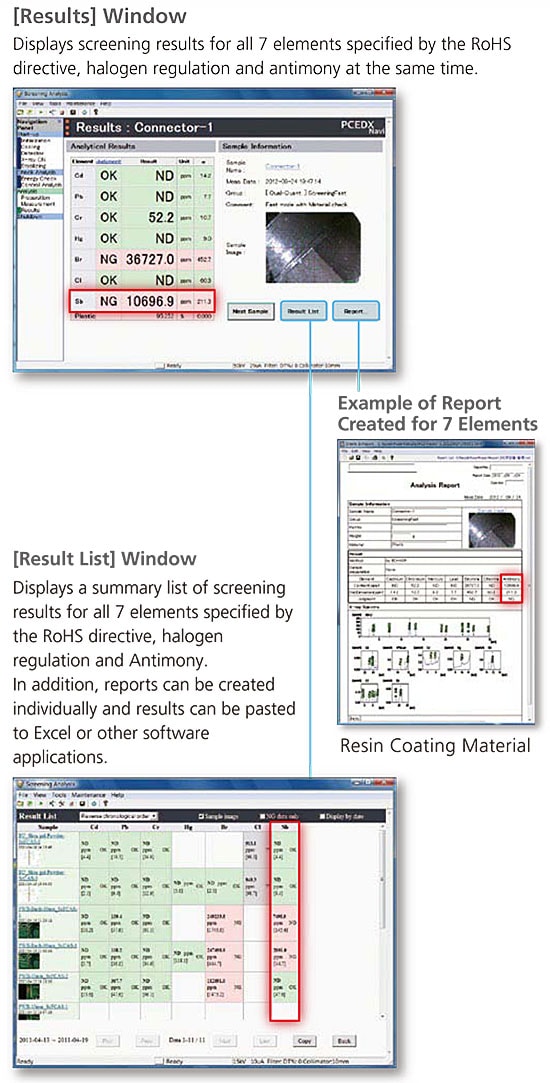

The analysis of a plastic (PVC cable insulation) is shown below. The OK, NG, gray-zone evaluation with respect to the control values is easily obtained.

* The control values in the results below are set to the maximum permitted concentrations under the RoHS Directive.

Receiving inspections and other screening for pass/fail evaluation of the harmful element content against control value standards in numerous products require higher operation efficiency and lower running costs in the workplace.? EDX-LE meets all these requirements.

As the detector requires no cooling by liquid nitrogen, running costs are significantly reduced.

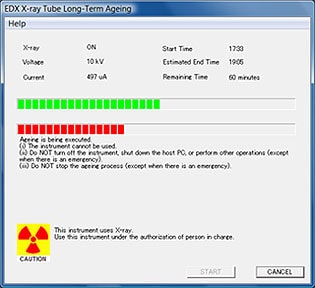

X-ray tube automatic aging

Aging to extend the service life of the X-ray tube is an essential instrument management process. X-ray tube aging is performed automatically when the instrument is restarted after a long period. This improves operation and prevents breakdowns.

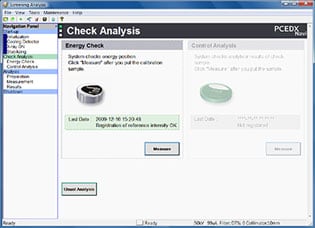

Instrument Check Window

Instrument calibration is required to obtain stable analysis results. However, the calibration operations and evaluation should be as quick as possible. EDX-LE supports an energy check and quantitation value check on start-up. Calibration is performed automatically, if required.

As it may be necessary to change control values on a daily basis according to the product, the screening conditions can be easily changed to suit the control system. Efficient operations from the start of analysis to report creation are possible.

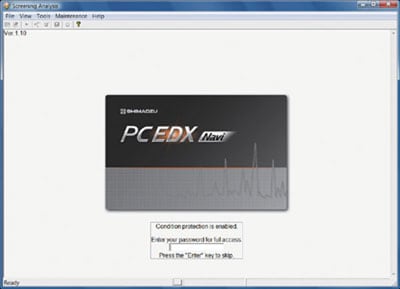

Software access restrictions prevent inadvertent changes to screening conditions by people without the authority to change the conditions.

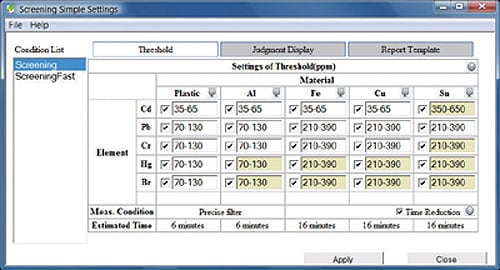

A threshold value can be set for each material and element. The screening evaluation method can be changed according to how the threshold value is entered. The lower limit of the threshold value can be observed for each material as an aid to setting the threshold value.

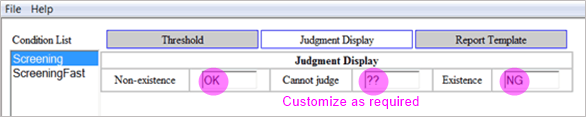

The method of displaying the evaluation results in the report (OK, gray-zone, NG) can be customized.

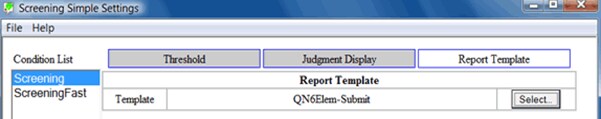

The report style can also be set. A template supplied as standard with the instrument can be selected.

A password can be set to restrict changes to the screening conditions and preferences, enhancing the security of software operation.

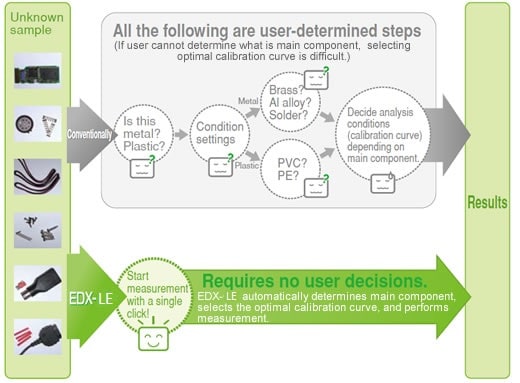

Start sample measurement from [Screening Analysis], using simple steps. Measurement condition selection, which typically relies on the judgment of the experimenter, is determined automatically.

Place the Sample

- After placement, the sample observation camera observes the sample and confirms the sample's analysis position.

Select Analysis Conditions/ Enter Sample Name

- The [Measurement Preparation] window displays the current sample image. Use this window to select analysis conditions and enter a sample name.

Display of Analysis Result

- After measurements are completed, [Pass/Fail Judgment], [Concentration], and [3σ(Measurement Variance)] are displayed for all 5 elements in an easy-to-understand layout.

A single click in the [Screening Analysis] window automatically performs everything from measurement to the display of results, in accordance with your pre-registered analysis conditions.

EDX-LE standard equipment includes all the functions required for RoHS/ELV analysis, providing users with the optimal RoHS/ELV analysis system, without needing special options.

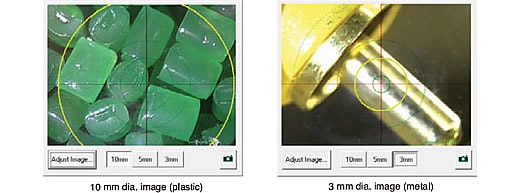

When measuring foreign substances and samples with multiple parts, the sample observation camera allows analysis position to be easily specified by checking the camera image. If the sample is small or if specific locations on the sample are being measured, the collimator can be used to change the Xray exposure region to 1 mm, 3 mm, 5 mm, or 10 mm diameter.

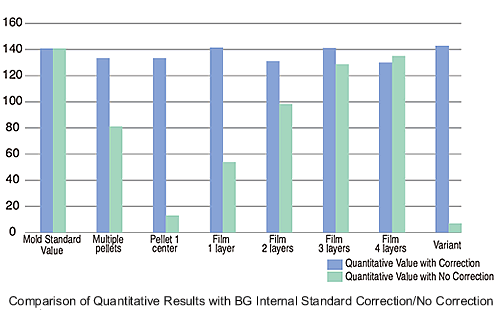

X-ray intensity differs with the shape and thickness of samples, even if they contain the same material, and will have an impact on quantitative values. EDX-LE utilizes a BG internal standard method to eliminate the effect of shape and thickness in order to provide highly precise results. *BG internal standards method: Fluorescent X-ray intensity of each element is standardized using scattered X-ray intensity.

List Creation Function

List stored data in Excel format.

Contrary to its compact-sized body, the EDX can accommodate larger samples than one would imagine, up to W 370 mm x D 321 mm x H 155 mm.

|

* |

Requires a Shimadzu service engineer to reconfigure software settings and confirm performance during initial setup |

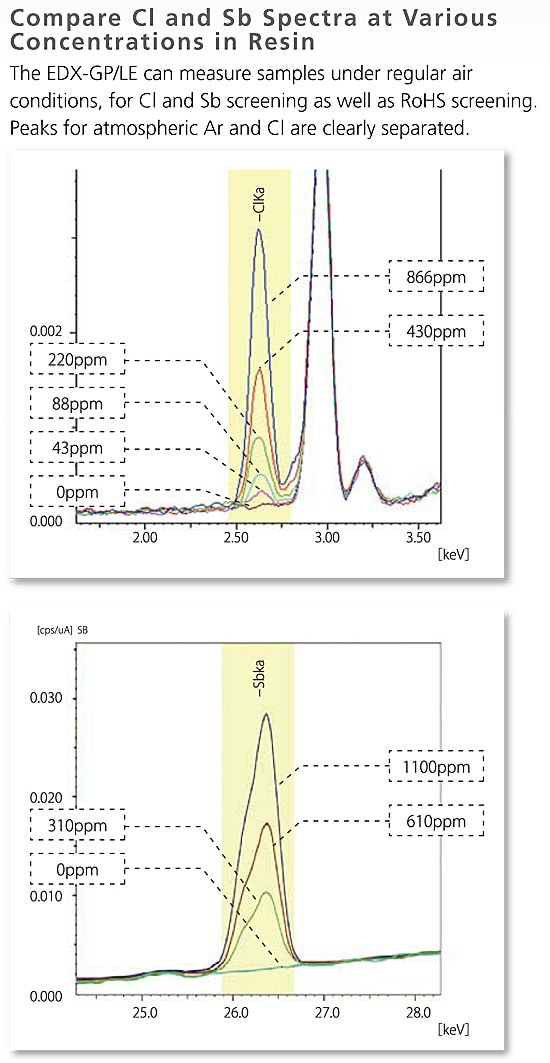

The same analytical conditions can be used to measure all 7 elements specified by the RoHS directive, halogen regulation and Antimony (Sb, Cd, Pb, Hg, Cr, Br, and Cl).

Features available after installing the kit:

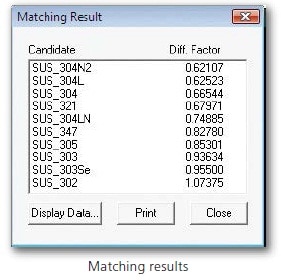

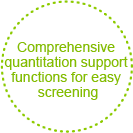

1. Elements not subject to RoHS/ELV regulations can be identified and quantitated.