Seawater, river water, effluent, sludge, air-borne dust

Metals, minerals, glass, ceramics, IC chips

Petroleum, oil, catalysts, chemical products, biodiesel

Blood, animals, plants, drugs, food products

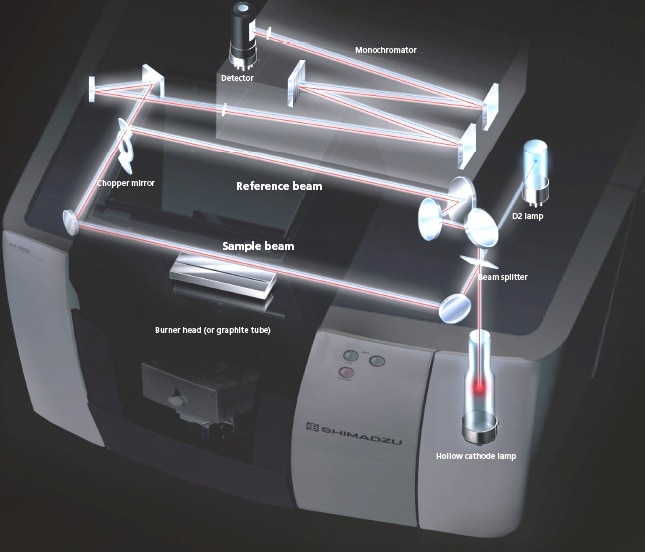

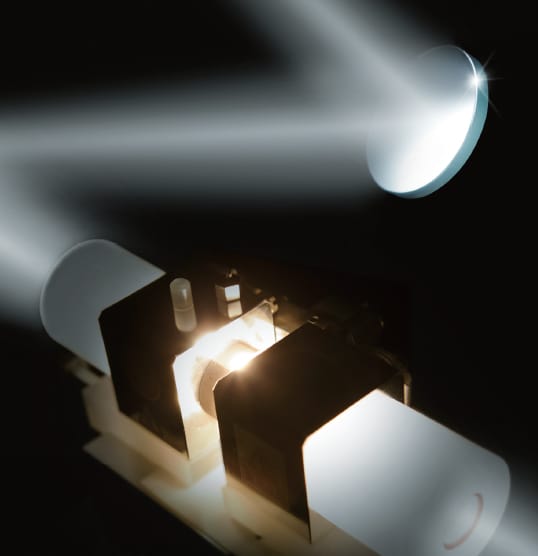

The AA-6880 Series incorporates newly developed 3D double-beam optics.

The optical system has been designed to produce maximum performance for each measurement method through optimal adjustment of the light beam and light beam digital filter, and by using optical components that restrict light losses.

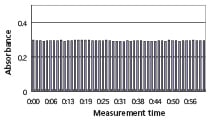

The graph shows the results of measurements on 2 ppm copper (Cu) conducted over at least one hour. (The plot shows mean values for 11 repeated measurements.) Over the course of more than 600 measurements, the instrument achieved a relative standard deviation within 1%.

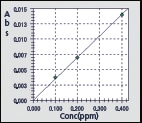

The graph shows the direct measurement results for 0.1 ppm lead (Pb).

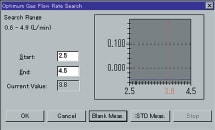

Automatic searching for optimal fuel gas flow rate (Japanese Patent 2099886). It is important to determine the optimal gas flow rate for the flame when using an organic solvent or after changing the burner height. The AA-6880F Series automatically optimizes the gas flow rate by measuring the changes in absorbance between a blank and a standard sample. The difference between the two is displayed on the screen. The gas flow rate achieving the highest sensitivity is detected and this value is automatically set as the gas flow rate value.

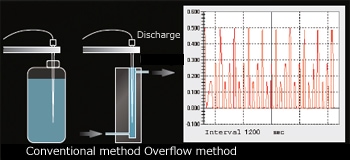

Great care must be taken to avoid carryover during flame analysis. The new ASC-6880 autosampler rinses the nozzle at the rinsing port on the overflow mechanism after each sample measurement is complete. This ensures 10-4 max. carryover during measurements of multiple samples. The graph shows the results of consecutive analyses of 10 ppm, 20 ppm, and 50 ppm sodium (Na) standard solutions in the EMISSION mode. No carryover could be detected when measuring the 10 ppm standard sample immediately after measuring the 50 ppm Na standard sample.

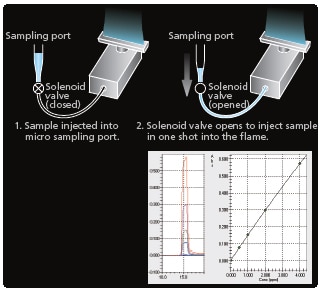

At least 1 mL (1000 μL) volume of a liquid sample is required for the continuous intake of sample during normal flame analysis. With micro sampling, however, approximately 50 to 90 μL of sample is injected in one shot into the flame and quantitation is based on the height and area of the peak signal obtained. This method offers the advantages listed below.

Advantages

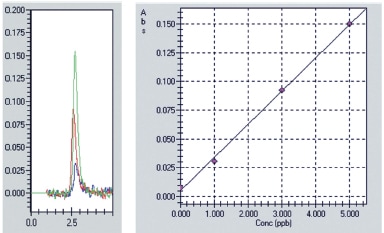

Examples of the measured waveforms (overlaid) and calibration curve for micro sampling analysis are shown to the right. A 2-ppm Cu standard solution was prepared by auto-dilution using the autosampler. The autosampler can also be used to conduct dilution measurements of the sample. (Injection volume: 90 μL)

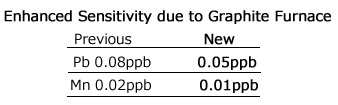

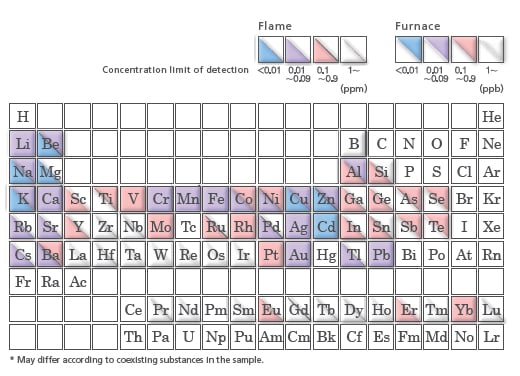

Advances in optics and a new graphite furnace design achieve improved lower limits of detection for furnace analysis (comparison with previous Shimadzu models). This superb analysis performance is possible in all fields.

- Multi-element analysis of small sample voMix and inject up to four sample types (diluted solution, standard solution, sample, matrix modifier, etc.). (Unmixed samples can also be injected.)

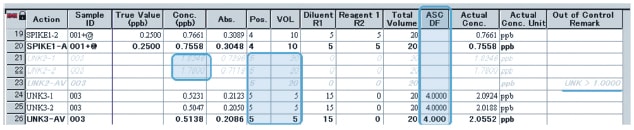

Example of Automatic Dilution and Re-Analysis

Analysis of cadmium (Cd): The maximum concentration of the calibration curve has been set to 1ppb. At 1.8ppb, the sample of [003] has exceeded the maximum concentration. As a result, it has been automatically diluted by four times and re-measured.

Measurement Example Showing High Sensitivity Analysis of 0 to 5 ppb selenium (Se): Sensitivity is adequate for 1 ppb measurements. (20 μL injected volume, Pd modifier, pyro-coated graphite tube)

Combination of a high-sensitivity optical sensor and unique digital temperature control technology achieves highly accurate temperature control in all temperature regions from drying to atomization. An electronic flow controller can precisely control the inner gas flow rate in 0.01 L/min units. These control techniques significantly enhance both the sensitivity and the data stability.

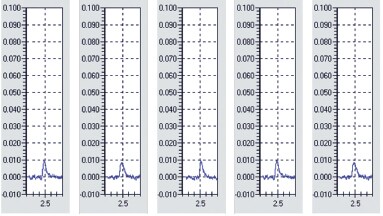

Measurement Example Showing High Stability

Analysis of 0.5 ppb lead (Pb): Approx. 5% relative standard deviation after five repeated measurements is adequate for quantitative analysis.

Safety is an extremely important consideration for flame atomic absorption spectrophotometers using acetylene gas.

The AA-6880 Series instruments incorporate a comprehensive range of safety mechanisms, including gas leak detectors.

- Multimode automatic gas leak check

Flame-retardant materials

UL 94V-0-rated flame-retardant materials are used for the instrument external

covers and atomizer unit. This superior design pays due consideration to safety.

Safe ignition switches

The switches perfectly fit finger contours and are positioned near the window.

To prevent inadvertent operation, both switches must be pressed simultaneously to start ignition.

Durable pipes and reliable couplings

All pipes are selected for durability and used with highly reliable couplings.

Clear window

The large window permits observation of the flame, and the burner can be easily accessed through the large opening. The window closes when released to eliminate the chance of it being left open.

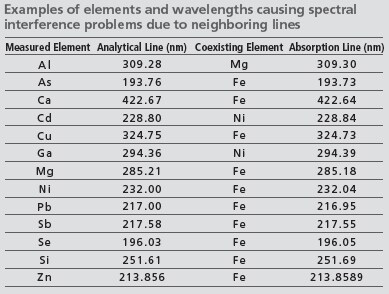

Selecting the optimal background correction method for each sample ensures accurate and reliable analysis results.

The SR method is suitable for samples containing elements that cause problems with spectral interference, as shown in the table to the left.