This product is only available in Europe, Southeast Asia and China.

The GC-2010 Pro represents a new generation in Routine GC. Fast oven heating and cooling reduces the analysis time and allow high sample throughput. Based on high-end GC technology, it combines easy operation with efficient analysis and excellence in sensitivity and precision.

Two analytical lines can be operated simultaneously for different applications

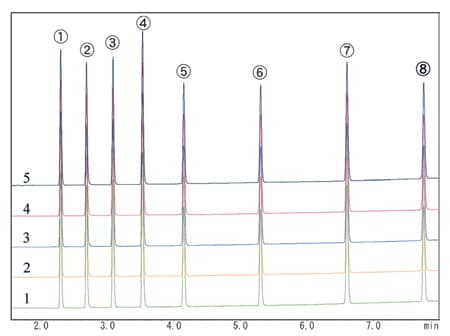

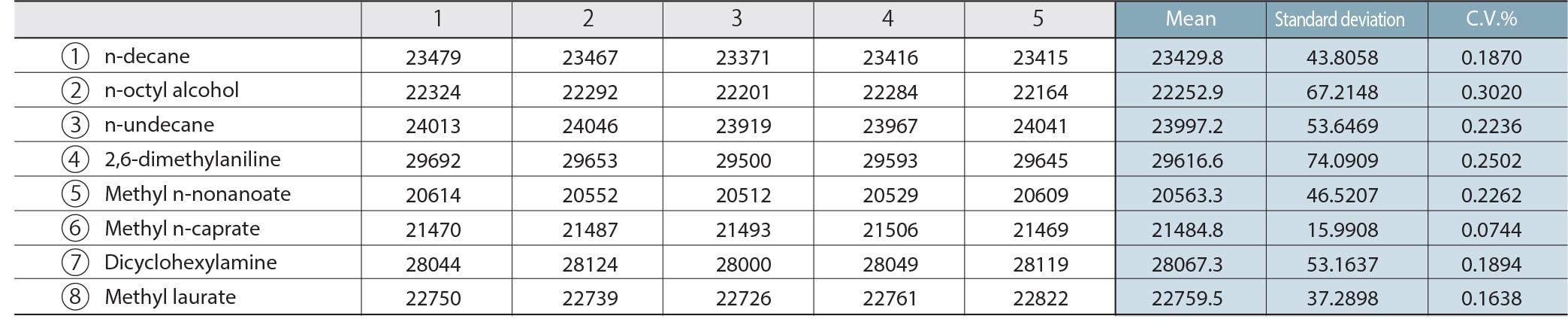

All units including the column oven, flow controller and sample injection unit are comprehensively optimized at the design stage to achieve world-class repeatability of peak area and peak height. The large vaporization capacity ensures excellent repeatability, even when using solvents that are highly volatile upon injection, such as acetone. Long-term stability of retention time is realized by the new room compensation technology built into the advanced flow controller (AFC).

Peak area reproducibility

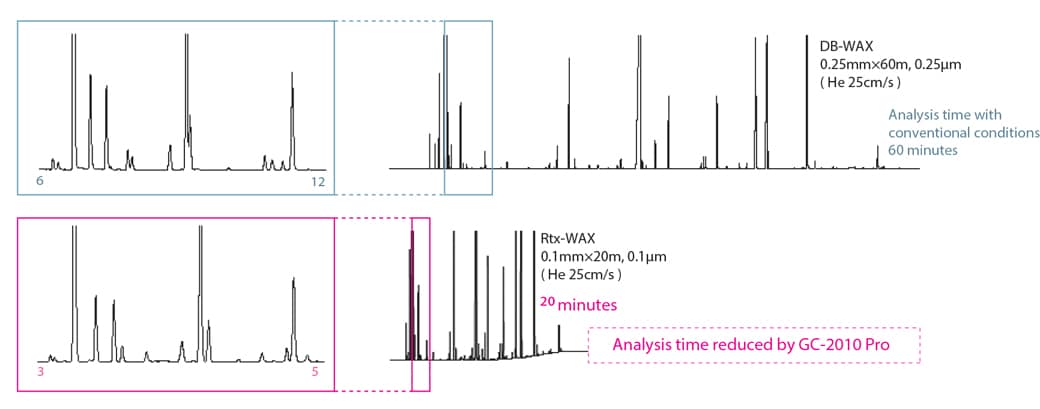

High-speed analysis with narrow bore capillary columns reduces analysis time and improves sample throughput. GC-2010 Pro has excellent flow and pressure control system, which can meet the requirements of rapid analysis with conventional configuration and effectively improve the analysis efficiency.

High-speed analysis of coffee flavoring

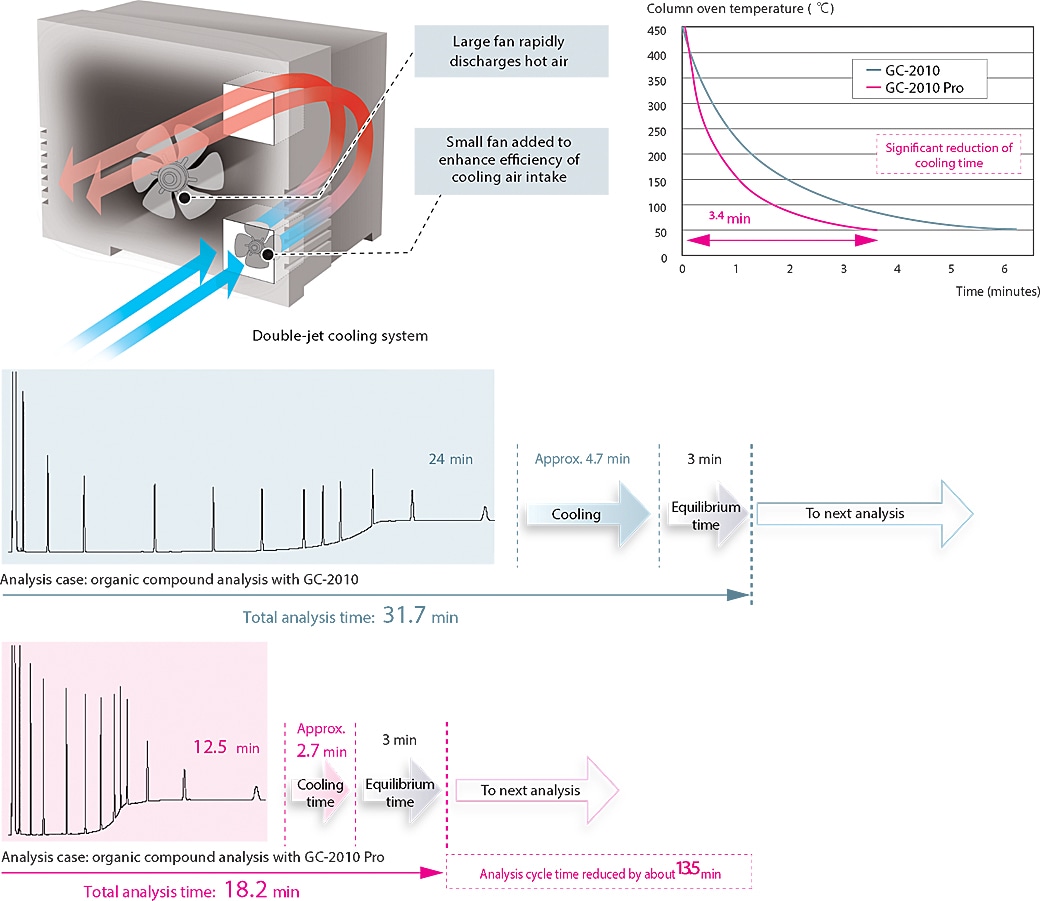

GC-2010 Pro incorporates a double-jet cooling system, which enables the reduction of cooling time from 450℃ to 50℃ in 3.4min, realizing more efficient and rapid cooling. In addition, with the ability of rapid heating, GC-2010 Pro can significantly reduce the analysis time.

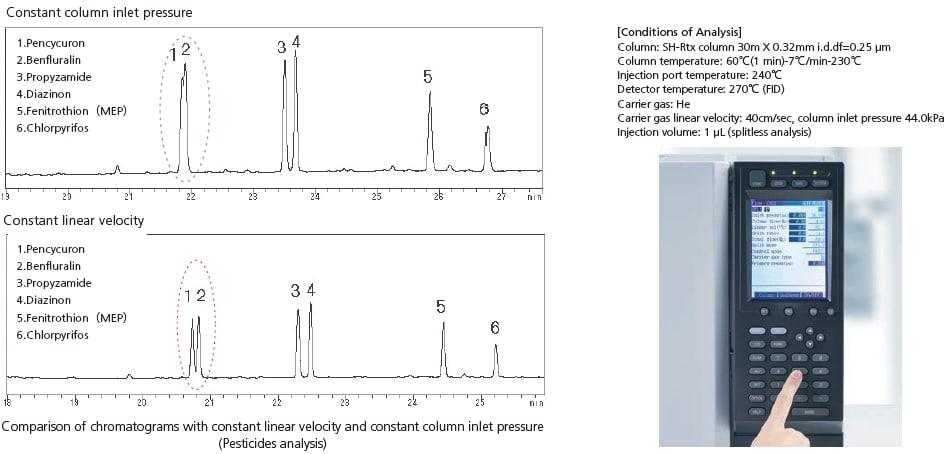

The constant linear velocity mode related to the separation performance is recommended for the carrier gas control and can obtain the optimum separation conditions in the shortest time compared with the previous control method by setting the column inlet pressure and flow.

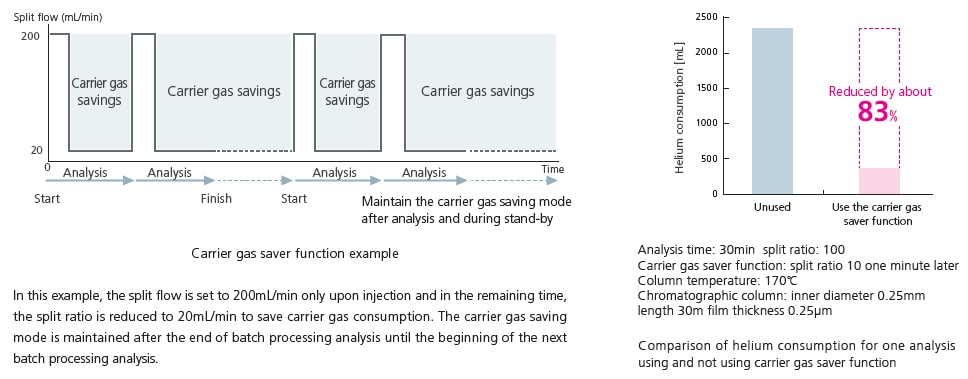

Reducing running cost by gas saving is an important issue in GC operation. GC-2010 Pro reduces gas consumption by decreasing of split ratio after injection as well as automatic shutdown functions after finishing all analysis.

In order to obtain good data, it is necessary to select an appropriate injection method according to the analysis purpose and sample. GC-2010 Pro can select the most suitable injection method from three injection units.

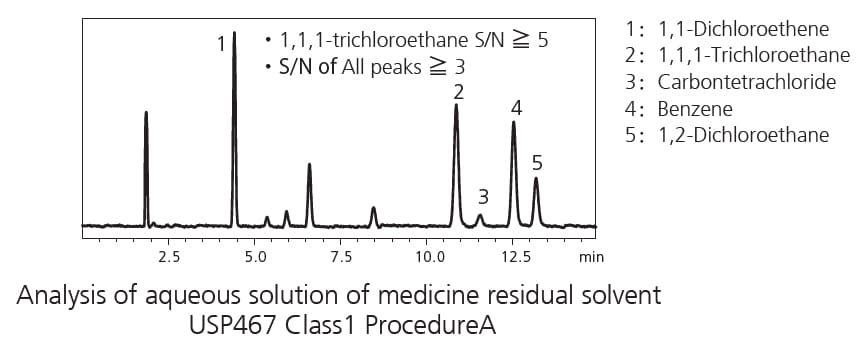

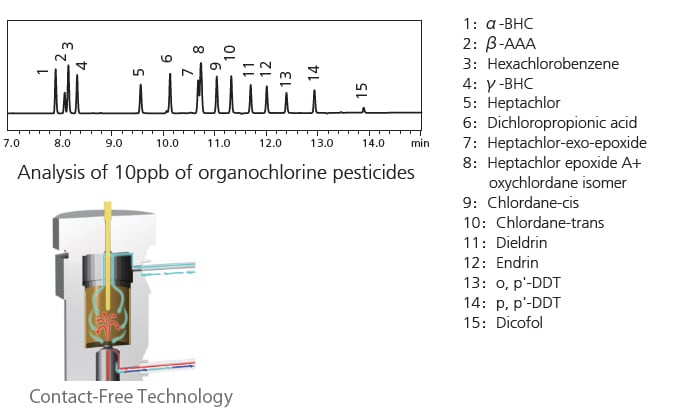

The full range of high-sensitivity detectors supports a wide variety of application analyses. Each detector is equipped with an advanced pressure controller (APC) that digitally sets the gas parameters of each detector. To ensure secure use of hydrogen the connector joints have reverse threads to prevent incorrect pipe connections (FID, FPD, FTD).

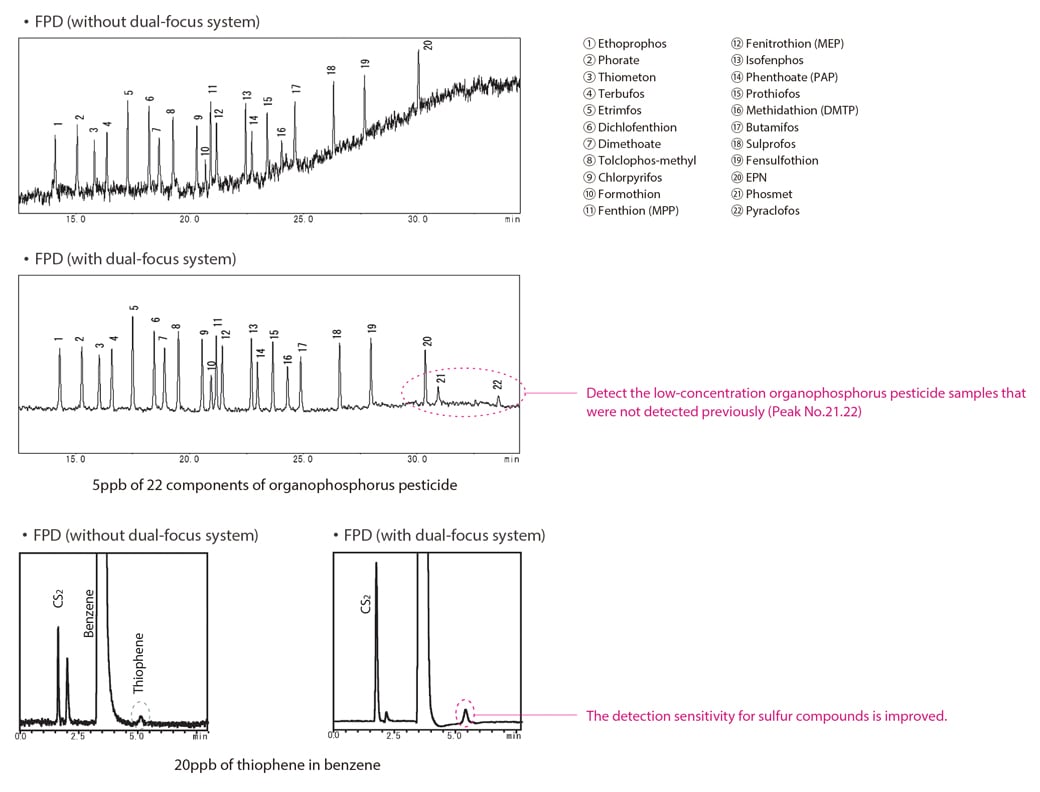

Responding to the ever increasing demands for trace level analysis, all detectors of GC-2010 Pro realize high sensitivity in miniaturization design. The new flame photometric detector (FPD) and flame ionization detector (FID) show significantly increased sensitivity.

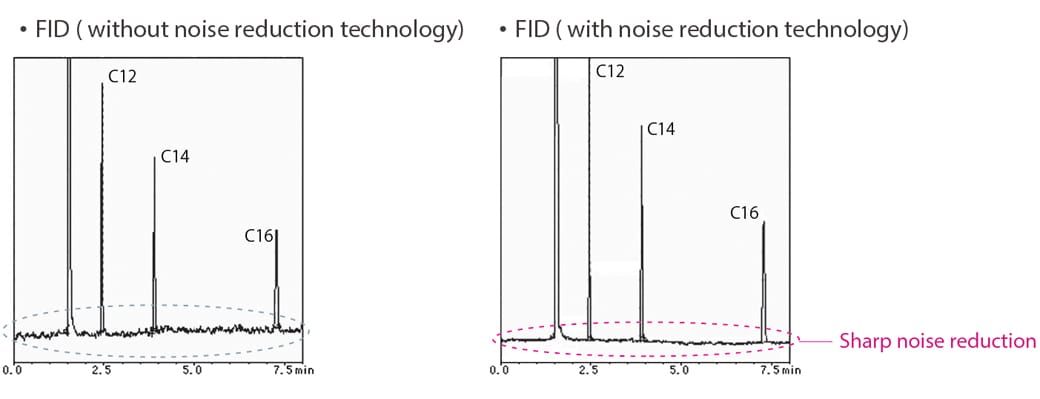

- Flame ionization detector FIDHigh-sensitivity has been achieved by thorough cleaning of detector gas lines and the latest noise-reduction technology.

Analysis of n-C12, 14, 16 / n-heptane solution

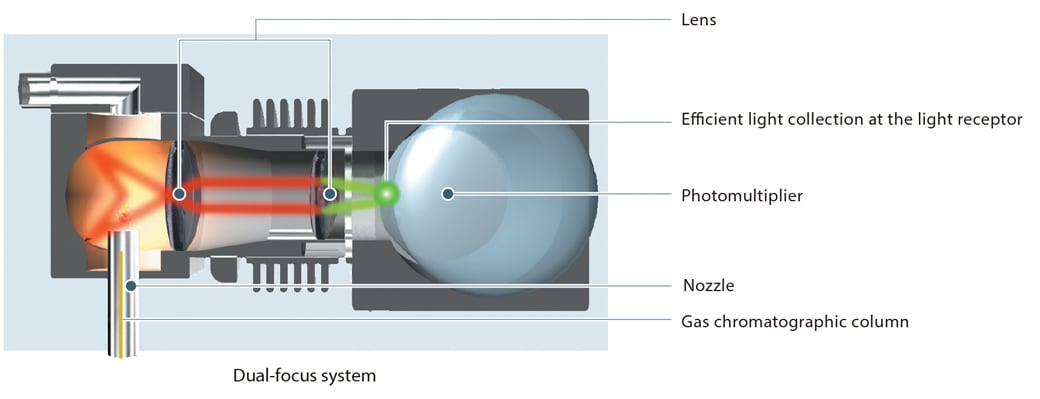

It achieves compact design and improves the flame stability by improving the nozzle form. In addition, the "dual-focus system" achieves excellent ultra high sensitivity. The dual-focus system adds a lens to the interference filter for efficient light collection at the photomultiplier light receptor.