The accumulation of lead in the body causes problems with the nervous system. A particular problem is the ingestion of lead through the food chain due to contamination of groundwater from tin-lead solder in waste automobiles and electrical goods being leached out by acid rain. As a result, the development of lead-free solder is being researched.

Metals including silver, copper, zinc, bismuth, and indium that can combine with tin were investigated in order to achieve a melting point as close as possible to the 183 °C melting point of tin-lead solder. Three classes of solder are available according to the balance between reliability and process temperature.

Generally, tin-silver-copper alloys are used for high-temperature applications; tin-silver-bismuth-copper alloys are used for medium-temperature applications; and tin-silver-bismuth alloys are used for low-temperature applications.

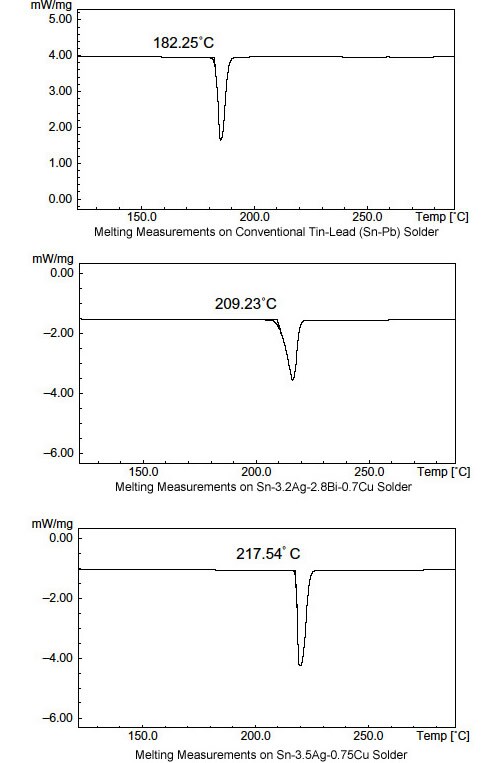

Melting measurements were conducted on conventional tin-lead (Sn-Pb) solder, medium-temperature Sn-3.2Ag-2.8Bi-0.7Cu solder, and high-temperature Sn-3.5Ag-0.75Cu solder using a DSC-60 Differential Scanning Calorimeter.

A newly developed high-sensitivity detector doubles the previous peak heights. The 1 µW (RMS) max. noise level permits cooling measurements without the need for options. Automatic detector cleaning.