Testing the strength and functionality of packaging materials is essential to ensure food products reach consumers fresh and undamaged. To aid the development and quality control testing of packaging materials, Shimadzu analytical and testing technologies allow the analysis of residual solvents in packaging materials, strength testing of adhesive seals, and checking of pin holes in packaged products.

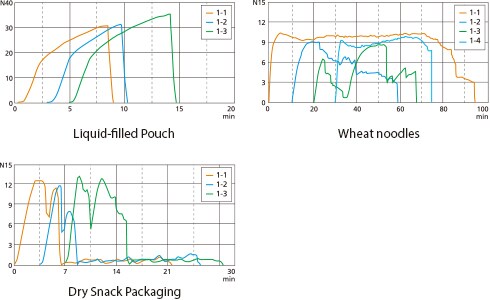

A wide range of materials, including aluminum and other metals and non-metallic materials such as paper and plastic, is used for packaging. According to their application, these materials must meet certain tensile, compression, and bending strength requirements, and if an adhesive is used, adhesive strength requirements. In the examples below, adhesive strength results for liquid-filled pouch, wheat noodle and dry snack package specimens are shown. In both instances, the adhesives meet the requirements of being strong enough to protect the contents, but weak enough so that the contents can easily be accessed by consumers.

Compact Table-Top Universal Tester

EZ Test

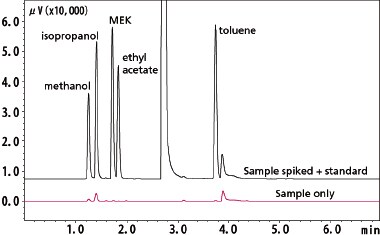

Quality control of residual organic solvents is required because the manufacture of food packaging materials and containers involves the use of organic solvents in printing inks and adhesives. This example shows analysis of residual organic solvents in dry snack packaging using headspace GC. Trace residual solvents were detected.

Headspace Analysis System

HS-20 + Nexis GC-2030 / GCMS-QP2020 NX

Residual organic solvents in dry snack packaging

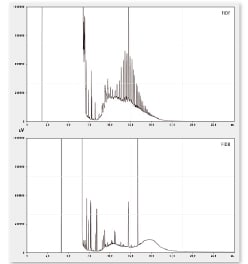

There's concern about the influence of mineral oil components such as MOSH (mineral oil saturated hydrocarbons) and MOAH (mineral oil aromatic hydrocarbons) on the human body. Food can get contaminated with MOSH/MOAH through contacts with packaging materials and printing colors of packaging. LC-GC online system with autosampler enables effective and high throughput analysis of MOSH and MOAH in food and food packaging. After separation in HPLC, MOSH and MOAH fractions are automatically transferred to GC and detected by two FID simultaneously. It‘s a powerful solution for the analysis of non-intentionally added substances (NIAS) such as mineral oil hydrocarbons.

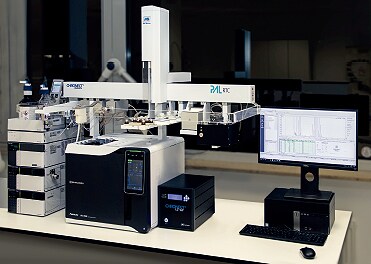

LC-GC Online System

with Autosampler for MOSH/MOAH Analysis*

Nexera X2 + Nexis GC-2030 + PAL Autosampler

Chromatogram of MOSH/MOAH in food and food packaging

* Configuration may not be available in all countries. Check with your Shimadzu representative.